News

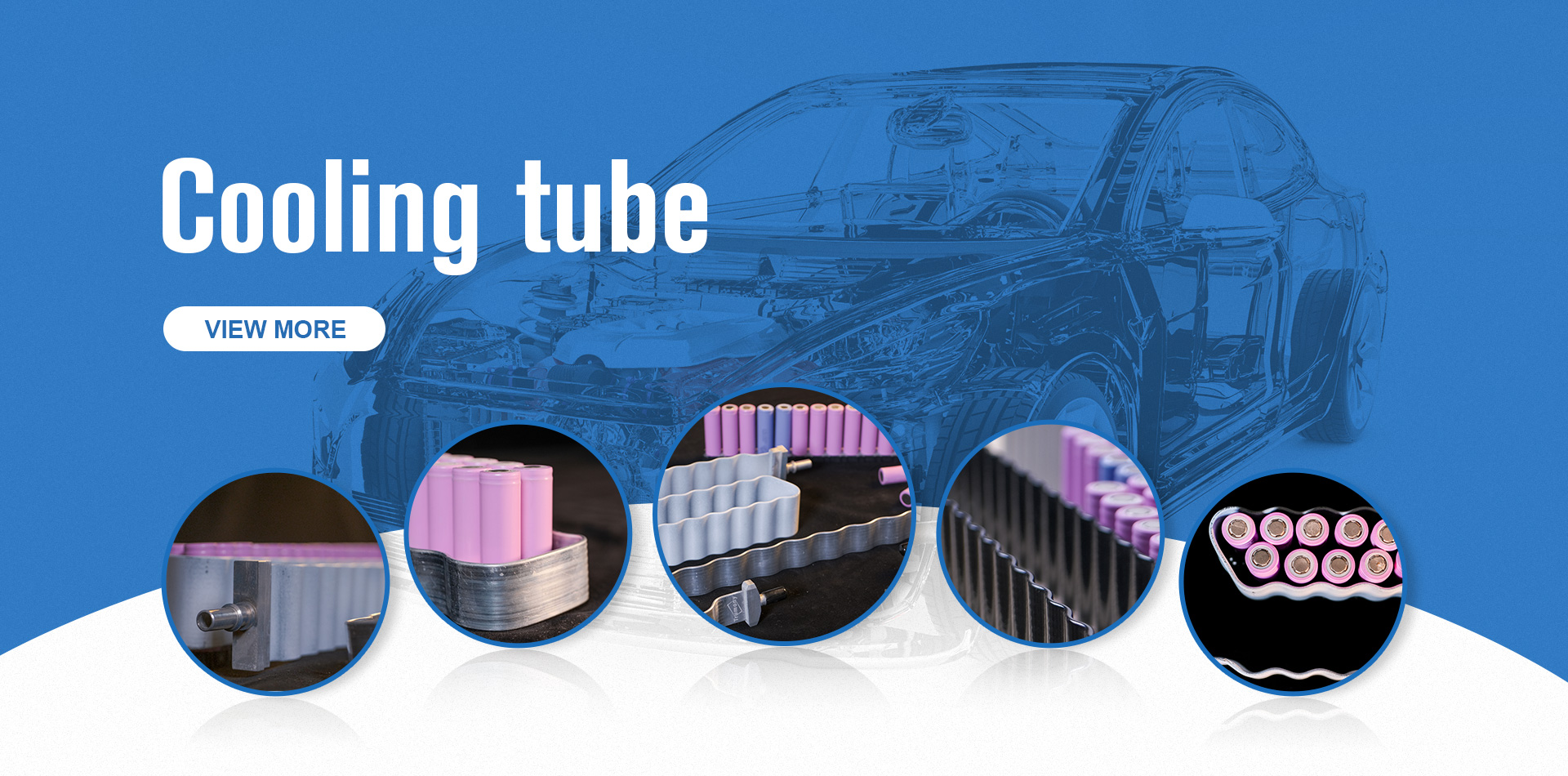

- How does liquid-cooling tube help thermal management of electronic equipment?Liquid-cooling tube, also known as cooling serpentine tube, is a heat exchange component commonly used in cylindrical batteries. The liquid-cooling tube uses a unique hollow structure pipe and is developed with high precision manufacturing quality. It has a large inner surface area can achieve more efficient heat conduction, so it is often used in battery packs with cylindrical cells. As we all know, high temperature is the invisible killer of electronic components, integrated circuits, etc. High temperature will not only shorten the service life of the equipment, cause unstable system operation, and even cause problems such as component burnout. Therefore, heat dissipation treatment of electronic components and integrated circuits cannot be ignored. There are many types of heat dissipation methods, such as liquid cooling, air cooling, and evaporator air cooling. Among these heat dissipation methods, liquid cooling stands out for its excellent heat dissipation efficiency, low space occupation and silent characteristics, and has been widely used. Liquid cooling devices usually use pumps to circulate the coolant in the liquid cooling tube and dissipate heat. Therefore, the liquid-cooling tube is an important part of the liquid cooling device. It can not only serve as a channel for the coolant to flow without contacting the heating element, but it can also serve as a heat transfer pipe, directly in contact with the heating element, absorbing the heat of the heating element and transferring the heat to the coolant. Normally, when a liquid-cooling tube doubles as a heat transfer pipe, you can generally change the material of the liquid-cooling tube, the composition of the coolant, and increase the contact area between the liquid-cooling tube and the heating element, the flow rate of the coolant in the liquid-cooling tube, etc. method to enhance the heat dissipation effect of the liquid cooling device. Liquid-cooling tubes are usually made of aluminum, copper alloy or a combination of the two. In terms of thermal conductivity, there are other materials that have better thermal conductivity than copper and aluminum alloys, such as silver, but silver is more expensive, so it is generally Silver is not used for liquid cooling tubes. The selection of materials for liquid-cooling tubes is determined by factors such as the material's price, processing difficulty, weight, hardness, and usage environment. It cannot just look at the thermal conductivity of the material. Therefore, changing the material of the liquid cooling tube to enhance the heat dissipation effect of the liquid cooling device has certain limitations. In the same way, the selection of coolant components is also determined by the price of the coolant, specific heat capacity, heat absorption capacity, usage environment and other factors. Therefore, changing the composition of the coolant to enhance the heat dissipation effect of the liquid cooling device also has certain limitations. Increasing the contact area between the liquid-cooling tube and the heating element will correspondingly increase the space occupied by the liquid cooling tube within the system, resulting in a reduction in the space utilization within the system. In addition, increasing the contact area between the liquid-cooling tube and the heating element also has many problems such as complicated design and increased cost The flow rate of coolant in the liquid-cooling tube is related to the density, viscosity of the coolant and the power of the pump. Among them, the power of the pump is the main factor that determines the flow rate of the coolant in the liquid-cooling tube. Generally speaking, the greater the power of the pump, the greater the flow rate of the coolant in the liquid cooling tube. As the power of the pump increases, the working energy consumption of the pump will also increase, the power consumption will increase, and the cost will increase. At the same time, as the power of the pump increases, the requirements for the pump will also increase, and the cost of the pump will also increase

2024 03/25

- Welcome to visit our booth -2024 Battery Energy Storage Exhibition in KoreaTrumony Aluminum Limited brought high-quality exhibits to the three-day Korean Battery Exhibition (InterBattery) held at the COEX Exhibition Center in Seoul, South Korea. We sincerely invite all partners and industry friends to visit our booth: E126, Hall E Exhibition time:24.03.06(Wed)-03.08(Fri) Opening time:09:00 - 18:00 Exhibition industry:battery energy storage Organizer:Korea Battery Industry Association COEX Location:Coex Hall A.B.C.D.E.Platz, Seoul, Korea Held period: once a year

2024 03/07

- Exhibition Invitation | 2024 Battery Energy Storage Exhibition in Seoul, KoreaThe 2024 Seoul Battery Energy Storage Exhibition will be held in Seoul, South Korea from March 6th to 8th. Trumony invites all attendees to visit our booth E126 to explore advanced battery thermal management solutions Time:24.03.06(Wed)-03.08(Fri) Location:Coex Hall A.B.C.D.E.Platz, Seoul, Korea Booth No.E126 Exhibition Profile The exhibition has 2,200 booths, more than 500 exhibitors, and about 75,000 buyers. INTER BATTERY is Korea's leading battery exhibition, providing a platform to learn about the latest developments and trends in the global battery industry, and displaying new products and technologies from leading battery manufacturers and related companies. The product range covers batteries, capacitors, measurement/test equipment and other fields. The exhibition aims to expand and develop the global battery industry from mobile phone products to energy solutions. The Korea International Battery Conference and Forum will also be held concurrently with the exhibition, bringing together global professionals to discuss the current status and future of the battery industry, and providing participants with opportunities to establish effective business contacts. Trumony (TRUMONY ALUMINUM LIMITED) Mainly provides customers with battery thermal management solutions, liquid cooling system development, and liquid cooling systems.Design, delivery of liquid cooling materials, liquid cooling components, liquid cooling assemblies and other related services and products. Contact Person: Mr. Tracy E-mail: tracy@trumony.com F-Tel: +8613584862808 Fax: 86-512-62538616

2024 03/05

- Denso Developed Everycool, a cooling system for commercial Vehicle"Denso Corporation, a leading provider of automotive technology, has announced the development of an advanced cooling system that can provide comfort and energy efficiency in commercial vehicle engines when they are turned off. The product, named "Evervcool," will be launched in December 2023. This innovative cooling system represents another major breakthrough for Denso Corporation in the automotive technology field. The development of this system aims to address the issues faced by commercial vehicles when their engines are turned off, such as excessive interior temperature and energy waste. The "Evervcool" cooling system utilizes advanced technology to maintain interior comfort when commercial vehicles are not in operation. The key to this innovation lies in the system's ability to automatically adjust the cooling effect based on the interior temperature and external environmental conditions. When the vehicle is turned off, the system automatically starts and adjusts the cooling effect intelligently, ensuring that the interior temperature remains within a comfortable range. In addition to providing comfort, this cooling system also significantly improves the energy efficiency of commercial vehicles. Traditional cooling systems continue to operate even when the engine is turned off, consuming a considerable amount of energy. However, the "Evervcool" cooling system minimizes energy waste by intelligently adjusting the cooling effect, thereby enhancing the overall energy efficiency of commercial vehicles. The Chief Technology Officer of Denso Corporation stated, "We are proud to have developed this advanced cooling system. 'Evervcool' will provide higher comfort and energy efficiency for commercial vehicles, offering users a better experience." Denso Corporation has reportedly reached cooperation agreements with several commercial vehicle manufacturers and will begin launching the "Evervcool" cooling system in December 2023. This innovative cooling system will first undergo pilot testing on selected commercial vehicle models to validate its performance and reliability. With further research and improvement, Denso Corporation plans to expand the application of this advanced cooling system to more commercial vehicles. The introduction of this cooling system will bring about significant changes in the commercial vehicle industry, not only enhancing comfort and energy efficiency but also reducing the negative impact on the environment. This innovative cooling system is expected to become a benchmark in the commercial vehicle industry, leading the industry's development direction. In summary, the launch of the "Evervcool" cooling system will bring higher comfort and energy efficiency to the commercial vehicle industry. As a leading provider in the automotive industry, Denso Corporation continuously brings advanced solutions through innovation and technological breakthroughs. With the application of the "Evervcool" cooling system in commercial vehicles, Denso Corporation will continue to drive the development of the automotive industry and provide users with a better travel experience." #Aluminum Micro channel Tube, Cooling Ribbon, Liquid Cooling Tube For EV, Water Cooling Tube For EV, cooling plate for prismatic cells#

2023 09/13

- All Liquid-Cooled Ultra Fast Charging StationThe first all-liquid-cooled ultra-fast charging station for new energy vehicles in Guangxi Zhuang Autonomous Region has been completed and put into operation in Nanning city. The completion of this charging station marks an important step for Guangxi in the construction of new energy vehicle charging infrastructure, providing strong support for the development of new energy vehicles in the region. It is understood that this new energy vehicle all-liquid-cooled ultra-fast charging station is located in the Jiangnan District of Nanning city, covering an area of approximately 5,000 square meters, with a total investment of 10 million yuan. The charging station is equipped with 10 all-liquid-cooled ultra-fast charging piles, each of which can charge 4 new energy vehicles simultaneously. The charging power can reach 350 kilowatts, which is more than 10 times faster than traditional charging piles. In addition, the charging station is also equipped with an energy storage system, which can provide stable power supply to the charging piles during peak periods, ensuring charging efficiency and quality. The construction of this charging station is one of the important measures taken by the Guangxi Zhuang Autonomous Region government to actively promote the development of new energy vehicles. The government of Guangxi Zhuang Autonomous Region stated that new energy vehicles are the future direction of the automotive industry and an important way to achieve sustainable development. In order to accelerate the popularization and promotion of new energy vehicles, the government will increase the construction of new energy vehicle charging infrastructure, improve the number and speed of charging piles, and enhance the quality and efficiency of charging services. The completion of the all-liquid-cooled ultra-fast charging station for new energy vehicles is of great significance to the development of new energy vehicles in Guangxi Zhuang Autonomous Region. Firstly, the operation of the charging station will greatly improve the charging efficiency of new energy vehicles, shorten charging time, enhance user experience, and further promote the popularization of new energy vehicles. Secondly, the construction of the charging station also brings new development opportunities to the new energy vehicle industry chain in Guangxi. With the increase of new energy vehicles, the demand for charging facilities will also increase significantly, which will drive the development of related industries such as charging equipment manufacturing, charging pile installation, and operation and maintenance, creating new impetus for economic growth and employment in Guangxi. In the future, the government of Guangxi Zhuang Autonomous Region will continue to increase investment in the construction of new energy vehicle charging infrastructure, promote the intelligence and networking of charging piles, and improve the convenience and reliability of charging services. At the same time, the government will strengthen cooperation with new energy vehicle manufacturers, promote technological innovation and industrial upgrading of new energy vehicles, and further enhance the competitiveness of the new energy vehicle industry in Guangxi. In conclusion, the completion and operation of the first all-liquid-cooled ultra-fast charging station for new energy vehicles in Guangxi injects new vitality into the development of new energy vehicles in the region. This marks an important progress in the construction of new energy vehicle charging infrastructure in Guangxi Zhuang Autonomous Region and lays a solid foundation for the development of the new energy vehicle industry chain in the region. It is believed that with the strong support of the government of Guangxi Zhuang Autonomous Region, the new energy vehicle industry in Guangxi will have a broader development prospect. #Liquid Cooling Tube For EV, Water Cooling Tube For EV, cooling plate for prismatic cells

2023 08/28

- Byd has teamed up with Ayala to sell electric cars in the Philippines-New EnergyIn a move to promote sustainable transportation and reduce carbon emissions, Chinese electric vehicle manufacturer BYD has partnered with Ayala Corporation, one of the largest conglomerates in the Philippines, to bring electric vehicles (EVs) to the country. The collaboration aims to provide Filipinos with a greener and more efficient mode of transportation. Under this partnership, BYD will supply Ayala with a range of electric vehicles, including sedans, SUVs, and electric buses. These vehicles will be made available for both private and public use, catering to the needs of individuals, families, and businesses alike. With the increasing demand for eco-friendly vehicles worldwide, this collaboration presents a significant opportunity for both companies to tap into the growing EV market in the Philippines. Ayala Corporation, known for its diverse portfolio of businesses, including real estate, banking, and telecommunications, has been actively seeking ways to contribute to sustainable development. This collaboration with BYD aligns with Ayala's commitment to explore and invest in technologies that promote environmental sustainability. BYD, a global leader in the EV industry, is renowned for its cutting-edge technology and commitment to innovation. The company has been at the forefront of electric vehicle development for over a decade and has established itself as a trusted brand in the market. BYD's electric vehicles offer not only zero-emission transportation but also superior performance and advanced safety features, making them an attractive choice for consumers. The introduction of electric vehicles in the Philippines comes at a time when the country is grappling with air pollution and traffic congestion issues. With its rapidly growing population and urbanization, the Philippines has seen a surge in the number of vehicles on its roads, contributing to environmental degradation. The partnership between BYD and Ayala aims to address these challenges by providing a sustainable transportation solution that reduces carbon emissions and promotes a cleaner environment. In addition to supplying electric vehicles, BYD and Ayala will also establish charging infrastructure across the country. This will include the installation of charging stations in key locations such as shopping malls, commercial centers, and residential areas, making it convenient for EV owners to charge their vehicles. The availability of charging infrastructure is crucial for the widespread adoption of electric vehicles, as it addresses the issue of range anxiety and encourages more people to switch to EVs. The collaboration between BYD and Ayala is expected to have a significant impact on the EV market in the Philippines. By combining BYD's expertise in electric vehicle manufacturing and Ayala's extensive network and market reach, the two companies are well-positioned to drive the adoption of electric vehicles in the country. This partnership not only contributes to the government's efforts to reduce carbon emissions but also supports the Philippines' transition towards a more sustainable and eco-friendly transportation system. With the launch of electric vehicles in the Philippines, BYD and Ayala are poised to revolutionize the automotive industry and set a new standard for sustainable transportation. The availability of electric vehicles will not only benefit the environment but also improve the quality of life for Filipinos by reducing air pollution and providing a more efficient mode of transportation. As the demand for electric vehicles continues to grow globally, this collaboration marks a significant milestone in the journey towards a greener and cleaner future. #Cooling Pipe, cooling plate for prismatic cells, Aluminum Tube,Oil Cooler Tube ,Cooling Ribbon,Microchannel Tube,cooling plate for ev,

2023 08/16

- Toyota and other three companies joint venture 1 billion to build an autonomous driving platformToyota and two other companies jointly invest 1 billion dollars to establish an autonomous driving platform Tokyo, Japan - In a major move towards the future of transportation, Toyota Motor Corporation, along with two other leading companies, has announced a joint venture to establish a cutting-edge autonomous driving platform. The partnership, which includes Denso Corporation and Aisin Seiki Co., aims to invest a total of 1 billion dollars to develop advanced technologies and systems for self-driving vehicles. The three companies have long been at the forefront of automotive innovation, and this collaboration further solidifies their commitment to shaping the future of mobility. By pooling their resources and expertise, they hope to accelerate the development and deployment of autonomous driving technology, making it safer and more accessible for everyone. The newly formed joint venture, which will be called "Autonomous Driving Platform Development Corporation," will be based in Tokyo and will begin operations in April 2022. The platform will focus on developing a unified and scalable autonomous driving system that can be adopted by various automakers around the world. This open approach aims to create a standardized platform that promotes collaboration and enables seamless integration of autonomous driving technology across different vehicle models. The investment of 1 billion dollars will be used to fund research and development activities, as well as the establishment of a state-of-the-art testing facility. The facility will serve as a hub for testing and validating autonomous driving technologies, ensuring their safety and reliability before they are deployed on public roads. One of the key objectives of the joint venture is to enhance the capabilities of autonomous vehicles to operate in complex driving scenarios. By leveraging artificial intelligence and advanced sensor technologies, the platform aims to enable self-driving cars to navigate through challenging environments, such as crowded city streets and unpredictable weather conditions. The partnership between Toyota, Denso, and Aisin Seiki represents a significant step towards achieving a future where autonomous vehicles are a common sight on roads worldwide. It also highlights the importance of collaboration in overcoming the technical and regulatory challenges associated with self-driving technology. Commenting on the joint venture, the President of Toyota, Akio Toyoda, emphasized the need for collaboration in the automotive industry. He stated, "By working together with other companies, we can create a mobility society that is safer, more sustainable, and more convenient for everyone. This joint venture is a testament to our commitment to making autonomous driving a reality." The announcement of the joint venture comes at a time when autonomous driving technology is gaining traction globally. Governments and automakers are increasingly investing in research and development to bring self-driving vehicles to market. The establishment of the Autonomous Driving Platform Development Corporation is expected to accelerate the pace of innovation and drive the adoption of autonomous driving technology on a larger scale. As the world moves towards a future of autonomous mobility, the collaboration between Toyota, Denso, and Aisin Seiki sets a strong precedent for industry-wide partnerships. With their combined expertise and financial backing, the three companies are poised to play a pivotal role in shaping the autonomous driving landscape and revolutionizing the way we travel. #Aluminum Water Cooling Plate, Cooling Tube For ESS, Snake Tube For ESS, snake tube for ESS,Heat Exchanger Components#

2023 08/11

- Tengshi N8 All-Scenario SUV Launched on August 5thTengshi N8, a full-scene SUV, has been officially launched on August 5th. Tengshi Motors recently announced the release of their first full-scene SUV, Tengshi N8, which will further enrich the Chinese market for new energy vehicles and provide consumers with more choices. As the first full-scene SUV from Tengshi Motors, Tengshi N8 has attracted widespread attention with its outstanding design and excellent performance. The vehicle adopts a family-style design language, combining power and dynamism, with smooth lines that highlight its sporty and modern tech feel. Tengshi N8 is equipped with a high-performance electric motor, delivering impressive power. It is reported that the motor has a maximum power of 200 horsepower, peak torque of 300 Nm, and a range of over 500 kilometers under comprehensive driving conditions. This breakthrough in range will further meet users' demand for long-range driving and provide a more convenient travel experience. In addition to its impressive performance, Tengshi N8 also comes with abundant intelligent technology configurations. The vehicle is equipped with the latest generation of intelligent driving assistance systems, including automatic parking, adaptive cruise control, and lane-keeping assistance, greatly enhancing driving safety and convenience. Furthermore, Tengshi N8 is equipped with an intelligent infotainment system that supports voice control, navigation, and music playback, providing users with a more intelligent driving experience. Tengshi Motors has been committed to the development and production of high-quality new energy vehicles, continuously promoting the development of China's new energy vehicle industry. The launch of Tengshi N8 marks a further expansion of Tengshi Motors' presence in the SUV market, providing consumers with more choices to meet their different needs. The launch of Tengshi N8 is of great significance to the Chinese new energy vehicle market. In recent years, with the increasing awareness of environmental protection and the government's greater support for new energy vehicles, China's new energy vehicle market has shown rapid growth. The launch of Tengshi N8 will further drive the development of China's new energy vehicle market and make a positive contribution to the transformation and upgrading of China's automotive industry. In summary, as the first full-scene SUV from Tengshi Motors, Tengshi N8 boasts outstanding design, excellent performance, and abundant intelligent technology configurations. Its launch will further enrich the Chinese market for new energy vehicles and provide consumers with more choices. The launch of Tengshi N8 will drive the development of China's new energy vehicle market and make a positive contribution to the transformation and upgrading of China's automotive industry. Consumers can look forward to the arrival of this new model and enjoy a more intelligent and environmentally friendly travel experience. #Aluminum Cooling Plate, Aluminum Water Cooling Plate, Cooling Tube For ESS, Heat Exchanger Components, Snake Tube For ESS, cooling plate for prismatic cells, snake tube for ESS#

2023 08/08

- Evx Gravity Energy Storage SystemThe world's first grid-scale gravity energy storage system, EVx, has entered the first phase of testing, according to recent reports. Developed by a clean energy technology company, the system aims to address the instability and intermittency issues of renewable energy generation, providing a stable and reliable storage solution for the power grid. The EVx gravity energy storage system utilizes innovative technology to convert excess electricity into potential energy and release it when needed. It consists of a 100-meter storage tower and a set of gravity blocks. When there is surplus electricity supply, the power is used to lift the gravity blocks to the top of the storage tower, converting the excess electricity into gravitational potential energy. When there is a peak in electricity demand, the storage tower releases the gravity blocks, driving a generator through gravity to meet the grid's needs. The EVx system not only possesses efficient storage and release capabilities but also features fast response times. Compared to traditional storage systems, EVx has a faster response speed, able to start and operate within seconds, effectively reducing the response time for power dispatch and improving the stability of the power system. It is reported that the EVx gravity energy storage system has undergone a series of successful experimental verifications, storing a large amount of electricity and quickly releasing it when needed to meet the grid's demands. This achievement has attracted widespread attention and interest from the domestic and international energy industry. Experts believe that the introduction of the EVx gravity energy storage system provides a new solution for renewable energy generation. Renewable energy generation is characterized by its instability and intermittency, while the EVx system can efficiently store excess electricity and release it quickly, providing stable support for the power system. This not only helps improve the reliability of the power system but also reduces reliance on traditional energy sources, promoting the development of clean energy. Currently, the EVx gravity energy storage system has entered the first phase of testing and is expected to be officially put into use in the next few years. Experts are optimistic about the system's development prospects and look forward to its significant contributions to global energy transition and sustainable development. #Heat Exchanger Components,Snake Tube for ESS,Snake Tube for EV#

2023 08/07

- BYD's billion India plant: on or not?Recently, it has been reported that Chinese electric vehicle manufacturer BYD's plan to build a factory in India has been canceled. This news has garnered widespread attention and speculation in the industry. It is understood that BYD originally planned to invest around $2 billion in India to establish a large-scale electric vehicle manufacturing plant to meet the country's demand for electric vehicles. However, due to a series of reasons, BYD has decided to cancel this plan. Firstly, the Indian government's policies are not supportive enough of the development of the electric vehicle industry. Despite the Indian government's promotion of electric vehicles, the support in terms of infrastructure and subsidy policies is not strong enough, which has raised doubts about the investment prospects of building a factory in India for BYD. Secondly, the demand for electric vehicles in the Indian market is not strong. Despite being the second most populous country in the world, the sales of electric vehicles in India have been low. According to statistics, electric vehicle sales in India only account for 1% of the overall automobile sales, which has raised concerns about the return on investment for BYD in building a factory in India. In addition, competition from domestic electric vehicle manufacturers in India is also one of the reasons for BYD's cancellation of the plan. Indian domestic companies such as Tata Motors and Mahindra & Mahindra have achieved certain achievements in the field of electric vehicles. Compared to international brands, domestic companies have certain advantages in terms of brand recognition and sales network, which has put BYD in fierce competition in the Indian market. Opinions on BYD's cancellation of the plan to build a factory in India are divided in the industry. Some believe that BYD's decision is wise because the demand for electric vehicles in the Indian market is not strong and the return on investment is unclear. Canceling the plan can avoid losses. Others believe that BYD should should continue to push forward with the plan to build a factory in India because electric vehicles are the future trend. Although the current demand in the Indian market is not high, with the improvement of government policies and the increase in consumer environmental awareness, there is huge market potential. For BYD, canceling the plan to build a factory in India may have a certain impact on its development in the Indian market. Currently, BYD mainly sells electric buses and electric taxis in the Indian market, and these models have maintained a high growth momentum in sales. However, if BYD cannot establish a production base in India, it will face higher import costs and competition pressure. Overall, the news of BYD canceling the plan to build a factory in India has sparked heated discussions in the industry. Whether in support or opposition, this decision will have a certain impact on BYD's development in the Indian market. It is worth paying attention to how BYD will respond to this challenge in the future. #Heat Exchange,Aluminum Water Cooling Plate for EV,Snake Tube for ESS,Cooling Pipe#

2023 07/26

- A new era of liquid-cooled energy storageFrom 14 to 16 June, CATL presented its newly upgraded all-scene energy storage solutions at EES Europe. It is reported that the exhibition attracted nearly 100 head enterprises to visit the booth for in-depth negotiation to sign and lock in more than 40GWh cooperation agreement. It is reported that CATL's EnerC Plus, the world's first transportation-integrated standard 20-foot container-type liquid-cooled energy storage system, was officially unveiled, which is equipped with CATL's new generation 306Ah battery cells, which can achieve 20 years of safe and reliable operation with a 10% increase in battery power and a back-to-back layout design that saves over 28% of floor space. In addition, CATL's family of high-safety, long-life advanced energy storage cells also made their debut at the exhibition, with battery specifications including 280Ah, 285Ah and 306Ah. Trumony specialises in energy storage liquid cooling solutions, with customised 1865, 2170, 4680 and various battery pack liquid cooling systems.

2023 06/20

- High-power IGBT Heat Dissipation Looks Towards Liquid CoolingHigh-power IGBT heat dissipation looks towards liquid cooling The insulated gate bipolar transistor (IGBT) is a key component in new energy conversion systems and high-voltage power switching devices, and is a representative platform device in high-power semiconductors. As a core functional device of a power electronic control circuit with high heat flow density, most of the failures of IGBT modules are related to thermal faults. The accumulation of heat can seriously affect the working condition and performance of the device, and if the temperature is too high (150°C), it can also pose a serious threat to the normal operation of the whole system module, or even damage it. Therefore, it is important to do effective thermal detection and management of IGBTs. Trumony has professional technical and design engineers who are able to design efficient, stable, compact and lightweight liquid-cooled heat transfer solutions for different IGBT projects. There are currently two types of IGBT heat dissipation: passive heat dissipation (heat dissipation by natural convection, which dissipates heat into the atmosphere without external forces) and active heat dissipation (such as air or water cooling). Passive heat dissipation includes Fin cooling: the heat generated by the IGBT will be dissipated by natural convection through the fins of the heat sink; Heat pipe cooling technology: heat pipes as two-phase heat transfer devices, with low heat transfer temperature difference, high heat transfer performance, high effective thermal conductivity advantages, simple working principle, no mechanical maintenance, purely simple and easy to operate passive method. (If fins are embedded, the efficiency of the heat dissipation will be increased even more) Phase Change Material (PCM) based heat dissipation: A new type of material that uses the release or absorption of latent heat during a phase change to control heat transfer. Active heat dissipation can effectively increase the cooling efficiency of a heat sink by 1 to 2 energy levels, and the cooling speed is faster, as the heat is dissipated by external forces. However, the appropriate heat dissipation method should be chosen for different use scenarios. Active cooling includes Air-cooled cooling technology: to provide sufficient cooling for IGBT cooling needs with high power and heat flux, measures to strengthen air-cooled cooling are mainly to increase the heat dissipation area, improve the heat transfer coefficient and rational design of air ducts, which are related to heat sink material, structure, airfoil, etc. Compared to natural cooling, forced air cooling can increase heat dissipation by a factor of 5 to 12. However, it is important to note that forced air cooling requires the configuration of fans and air ducts, which may generate a high level of noise. Liquid cooling technology: When the power of the equipment is very large (under the megavolt-ampere level), the forced air cooling technology cannot meet the higher cooling requirements due to the restrictions of the air ducts, air pressure and noise indicators, etc., water cooling is a good choice, and the cooling coefficient of the liquid cooling plate is about 100-300 times that of natural air cooling. Sometimes oil-cooled cooling is used in high voltage and high power power electronic devices due to insulation requirements.

2023 06/02

- Structural design of aluminium alloy battery pack casingAfter the rapid development in recent years, China has now become the world's number one country in terms of production and sales of new energy vehicles. With the introduction of the national subsidy policy for new energy vehicles in 2019 and the increase in range requirements, higher requirements for the energy density of the battery system have been put forward. There are two paths to improve the energy density of the battery: one is to increase the specific energy of the single cell; the other is to lighten the structure of the battery pack. To increase the specific energy of a single cell is technically difficult, with long R&D cycles and large capital investment, while making the structure of the battery pack lighter is easier to achieve. The use of aluminium alloys in automobiles has been commonplace for a long time. Aluminium has many advantages such as low density, high specific strength, thermal stability, corrosion resistance and good thermal conductivity, non-magnetic, easy to shape and high recycling value, making it an ideal material for lightweight battery pack design. At present, the mainstream scheme for battery pack shell materials is extruded aluminium alloy shell + PP/glass fibre composite top cover. From the point of view of current developments, the aluminium alloy shell and plastic top cover solution has the prospect of lightweighting. The aluminium extrusion profile + stir friction welding + MIG welding solution is used for the housing, which has a low overall application cost, meets the performance requirements and enables the integration of the circulating waterway for water-cooled batteries. The top cover uses a non-metallic top cover, mainly using PP/glass fibre + LFT-D moulding process, which can improve the efficiency of production and also meet the requirements of flame burning and sealing performance, and the mould cost is low. Aluminium alloy battery pack housings have been used in a number of new energy vehicles, such as the BYD Song and Tang, the Azera ES8 and the BAIC EV series. The housing can improve the energy density of the battery pack and increase the range. This shows that aluminium alloy battery pack shells have a broad market prospect.

2023 05/12

- A milestone breakthrough! --Condensed BatteryA milestone breakthrough! --Condensed Battery The introduction of CATL's 'Condensed Battery' will greatly promote the further development of battery technology and is expected to be widely used in new energy vehicles, energy storage, aviation and other fields in the future, further enhancing China's position and competitiveness in the global new energy industry, which is a major innovation that has been in the making for a long time, but also a It is a milestone breakthrough that is future-proof and fully meets the all-round requirements of electrification. With the gradual maturation of lithium-ion battery technology, its energy density is approaching its theoretical limit. This means that the traditional battery upgrade route faces many technical and manufacturing challenges. To meet full electrification and carbon neutrality targets, the industry urgently needs more advanced electrochemical material systems to achieve breakthroughs in higher energy densities. Of course, higher energy densities also mean greater risks and challenges, such as higher demands on battery safety. Therefore, the search for more advanced electrochemical material systems is the core crux of battery technology to achieve new breakthroughs. This new condensed battery is an innovation using solid-state battery technology, the core technology of which is the design and manufacture of condensed electrolytes. Traditional lithium-ion batteries use liquid electrolytes, which are flawed by the need to withstand extreme operating conditions such as high temperature and pressure and violent impacts within a short period of time, easily causing safety problems such as leakage and combustion. The condensed electrolyte, on the other hand, is a new type of electrolyte developed by CATL - high power bionic condensed electrolyte, which is a combination of various functional materials, with a combination of organic and inorganic materials, organic surface coating covered with inorganic raw materials, thus forming a fast ion conduction condensed electrolyte, which is non-flammable, zero volatile and This significantly improves the thermal stability of the battery, while regulating inter-chain interactions through the construction of a micron-level adaptive mesh structure, which enhances microstructural stability while improving battery kinetics and lithium ion transport efficiency. This condensed electrolyte produces a battery with the advantages of good safety, high energy density and low self-discharge rate. Specifically, it is safer in that the internal material is in a solid polymer and there is no liquid electrolyte that is prone to leakage. Secondly, the current of a condensed battery is more stable, its self-discharge rate is low, and its service life is longer, with higher energy density and better environmental adaptability." Future industrial innovation must collaborate across borders, break boundaries and develop comprehensively. CATL's condensed batteries are its latest innovation and an important milestone in its zero-carbon strategy, driving the next round of innovation. This innovation is not limited to one segment, but spans the entire industry and drives overall innovation.

2023 04/28

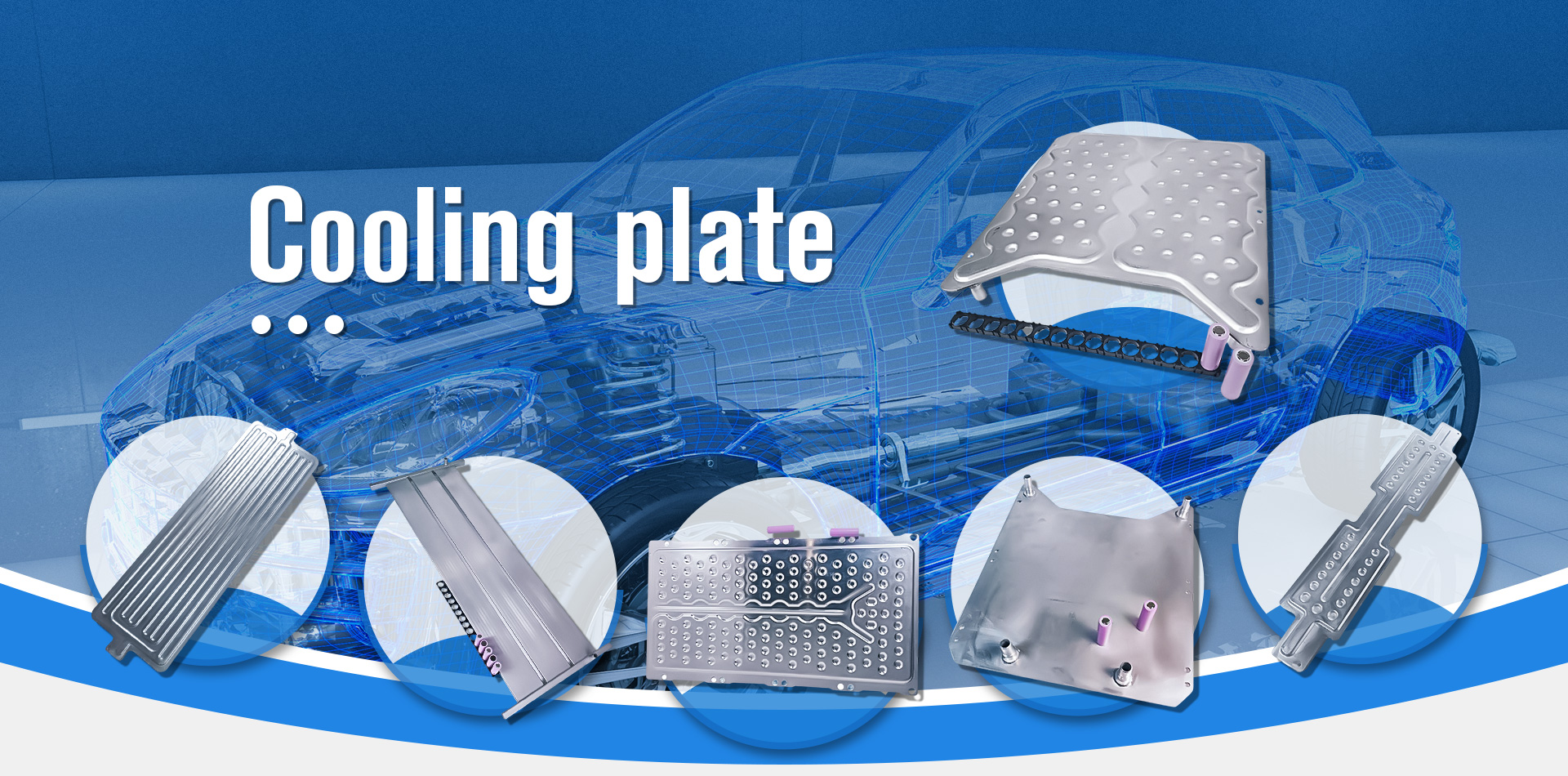

- Five ways to keep power batteries out of thermal runaway!Five ways to keep power batteries out of thermal runaway! Thermal runaway means that the battery generates a large amount of heat during operation and the temperature rises rapidly beyond the safety range, thus causing a fire or explosion. As one of the core components of a new energy vehicle, the power battery provides electricity to ensure the normal operation of the electric vehicle, and whether it can be kept away from thermal runaway directly affects the safety, service life, charge and discharge times of the power battery. How to keep the battery away from thermal runaway is a common concern of new energy vehicle users. To this end, TRUMONY has compiled the following methods to ensure the safety of the power battery and avoid thermal runaway from happening. 1. Adopt liquid cooling technology The liquid cooling system can be highly integrated with the battery pack, easy to install on site, occupying a small area, without worrying about dust, water vapour condensation and other problems. In the event of a thermal runaway, liquid cooling solutions can rely on a high flow of cooling media to force the battery pack to dissipate heat and redistribute heat between battery modules, which can quickly inhibit the continuous deterioration of thermal runaway and reduce the risk of runaway. Liquid-cooled panels, which are more commonly used in new energy vehicles, work by transferring excess heat generated by battery operation through contact with the surface of the plate type aluminium device. The liquid-cooled system uses the large heat transfer coefficient of liquid flow to transfer high levels of heat, which is eventually carried away by the coolant passing through the internal flow channels of the device. 2. Battery Management System A battery management system (BMS) is a system that monitors the status of the battery. It monitors parameters such as temperature, voltage, current and capacity of the battery and ensures its safety by controlling its operating status. 3. Protection measures In addition to controlling the temperature of the battery and using the BMS, other protective measures are required to ensure the safety of the battery. For example, guards can be placed around the battery to prevent it from colliding with other objects. Guards can also be installed to avoid short-circuiting and overcharging of the battery. 4. Choose a high-quality battery It is advisable to buy original chargers and batteries as these products have undergone rigorous testing and verification and are of safer and more reliable quality. Moreover, due to the complex internal structure of lithium batteries, if you are not a professional, do not dismantle the batteries at will to avoid damaging them and causing safety accidents. But the use of good quality batteries, but also only passive protection, and can actively protect the safety of the driver, the current stage or driving safety awareness, "safe driving" "active defensive driving" is the most important line of defence to protect the safety of drivers and passengers. 5. Correct use of batteries When using power batteries, there are some basic rules to follow. For example, avoid leaving batteries in hot or cold environments for long periods of time, avoid contact with water or other liquids, avoid charging and discharging batteries in hot or humid environments and do not overcharge them. The battery's charge level and state of charge should be checked regularly for wear and tear, damage or other abnormalities. If abnormalities are found, you should contact the manufacturer or a professional repairer for repair or replacement in order to avoid accidents. It is also very important to carry out regular maintenance on the power battery, which needs to be replaced in time for ageing. Translated with DeepL

2023 04/18

- The development of the stamping process in the automotive industryThe automotive stamping process is one of the most important and time-consuming steps in automotive manufacturing. The automobile mainframe includes four major processes: stamping, welding, coating and general. Among them, the stamping process can be basically divided into the parts of drawing, punching, trimming and shaping. Depending on the structural characteristics and complexity of different parts as well as the process characteristics of the vehicle company, the forming process varies from 4 to 6 course sequences. With the continuous development of the automotive industry, the stamping process is also being optimised and upgraded. Firstly, there is automation. Automation in the form of robots, automated guided vehicles and other machines will reduce the need for manual labour, resulting in faster production, more precision and fewer errors, and a better grasp of precision and quality throughout the stamping process. At present, the stamping line with the highest production speed is the German servo press line, with a continuous production speed of up to 17 times/minute for the whole line, while the domestic Jiji line can also reach 13 times/minute, which means lower production costs and higher profits. So 17 times/minute is certainly not the limit, and the future will certainly be towards higher production efficiency. At the same time, as consumers' personalisation needs become stronger and stronger, model changes are becoming more and more frequent, so the future of mould flexibility. Low cost is the main direction of development in the future. In addition, the speed and efficiency of stamping processes will increase in the future. new technologies such as 3D printing and laser cutting will enable more precise and faster production, less scrap consumption and, above all, greater flexibility, meaning that moulds can be dispensed with and individualised. This will allow manufacturers to produce parts quickly, reducing waiting times and enabling faster turnaround times. In addition, advances in computer-aided design (CAD) and computer-aided manufacturing (CAM) software will make the design process faster and more accurate. This will help to reduce errors, thus saving time and money. Not only that, but the emergence of disruptive technologies has also inspired the stamping process. Carbon fibre bodies and wheels are already being used on high-end luxury cars, which in itself is a material change from the usual sheet steel and aluminium, and so the forming process is moving beyond stamping.

2023 04/11

- Do you know what are the main components of an EV power pack?Power packs are the only source of power for purely electric vehicles and the range that an electric vehicle can travel depends on the power of the pack. The market is using high capacity cells or using more cells as a way of boosting the power pack electrical energy, however this can drive up the cost of the pack, so the focus needs to be on optimising the structure of the pack during the design process of the power battery, so what are the main components of an EV power pack? 1. Power Cell Module The role of the power battery module in the power pack is to store and release energy, which is the power source of the electric vehicle. The power battery module can be understood as the power battery monomer combined into multiple PACKs through series-parallel connection, PACK is a single component, which means packaging, encapsulation and assembly, and its process procedure includes three major parts: processing, assembly and packaging. After the power battery module has been structurally designed, it can be combined with the power battery management system and thermal management system to form a more complete power battery pack. The power battery pack is designed in a fixed position with the help of technology and structure, and together they play the function of electrical energy charging and storage. The fundamental role of the module is to fix, connect and secure the pack. Power battery cells and batteries are divided by positive materials, including lithium cobaltate, lithium manganate, lithium iron phosphate and lithium nickel cobalt manganate ternary materials. The structure of the power battery module should be fixed, supported and protected by the battery cells, which can be summarised into 4 major items: mechanical strength, electrical performance, thermal performance and fault handling capability. Power battery modules can be divided into three types according to the structural shape of the cells: cylindrical cells, square cells and soft packs, whose respective advantages and disadvantages are also obvious. To a large extent, the performance of the cells determines the performance of the power cell module, which in turn affects the performance of the entire power pack. Therefore, when designing a power pack, the material and shape of the cells must be considered in accordance with the design requirements of the vehicle. The ability of the power battery module to hold the cell in place and avoid performance-damaging deformation, to meet current-carrying performance requirements, to control the temperature of the cell, to cut off power in the event of a serious abnormality and to avoid the spread of thermal runaway are all criteria for assessing the merits of the power battery module. 2. Structural System The structural system includes the power battery PACK cover, tray, various metal brackets, end plates and bolts, which can be regarded as the "skeleton" of the power battery PACK, playing the role of support, resistance to mechanical shock, mechanical vibration and environmental protection (waterproof and dustproof). The power battery pack is loaded on the electric vehicle, the mechanical characteristics must be fully considered first, the product must have a certain strength and stiffness, in order to avoid deformation and functional abnormalities under mechanical loads such as vibration and shock, safety protection against collision, extrusion, tumbling, falling and other accident conditions. 3. Electrical System The electrical system mainly consists of high-voltage jumper or high-voltage harness, low-voltage harness and relays. The high-voltage harness can be regarded as the "artery and blood vessel" of the power battery PACK, which continuously transports the power from the heart of the power pack to each required component. The low-voltage harness can be seen as the "neural network" of the power pack, transmitting detection and control signals in real time.

2023 03/27

- Trumony to exhibit at the 15th China International Battery Fair 2023CIBF2023 will have an exhibition area of 240,000 square meters (12 halls). Since the launch of CIBF2023 on December 6, 2022, domestic and international companies have been enthusiastic about exhibiting at the show, and companies have been booking large booths. We Trumony will be exhibiting at the 15th CIBF 2023 as an exhibitor (standard booth 12B615), where we will showcase our most competitive battery pack liquid cooling components, liquid cooling system integration products and our excellent pre-sales, in-sales and after-sales services.

2023 03/22

- Trumony BTMS Solution For 4680 Battery CellTrumony, as one of Chinese professional EV battery thermal management solutions providers, was established in 2006 and mass production began in the Jan of 2007. With such rich experience in designing and manufacturing various specifications of cooling parts, Trumony has absolutely no doubt about tailoring an optimal complete thermal management solution package for 1865 and 2170 cells. As a common practice, 1865 cells and 2170 cells are surrounded by customized snake tubes through which coolants flow in and out to keep a favorable working temperature about 15 C to 35 C. Currently, Tesla and Panasonic developed a brand new cylindrical cell called 4680 cells. With a higher energy density, 4680 cells need an improved thermal management solution. Trumony is devoted in designing an exclusive snake tube for it. More info are on our official YouTube channel: https://www.youtube.com/watch?v=kJ1Hw2_Uu7k our Facebook Account: https: //www.facebook.com/aluminummaterial/

2022 09/13

- BTMS SimulationDefinition of Simulation. Finite Element Analysis (FEA) uses mathematical approximation to simulate real physical systems (product models, loads, working conditions). It decomposes the model into a limited number of interconnected sub-regions, namely units, and uses a limited number of units to approximate the real system, and simplifies the original complex system to obtain an approximate solution that can meet the requirements of engineering applications and scientific research. How simulation works in product development A product, from conceptual representation to drawings, models, to the actual product landing, needs to consider a variety of different materials, numerous production processes, or simple or complex production processes. The transition from unstable samples to stable and reliable batch products that can adapt to production changes requires a large number of tests and verifications that meet design parameters. Design and selection of materials, manufacturing and processing, testing and verification, each stage is accompanied by the consumption of time, manpower and material resource. The simulation can test the performance of the product under different conditions by modeling the product model, loading different material parameters and environmental conditions. The product materials required for actual production, the production process of actual operation, and one or more experiments, which are originally in reality, are moved to the computer in a simulated way, and after simulation, we will get the required data result. Through the simulation-aided design and development, the pre-design of the product can be effectively demonstrated, and the loss caused by the design error can be avoided. Simulation can guide design and experiments, so that customers can save the cost of design and development and improve the efficiency of design and development. The applications of simulation Commercial software companies have developed software and computing platforms for different disciplines and industries in combination with different professional characteristics and industry standards of various industries, so as to meet the needs of various industries for simulation computing. At present, there are many kinds of main finite element software. The commonly used simulation software in the automotive industry includes ANSYS series products, HyperWorks series products, MSC series products, and Abaqus software. From the stage of simulation analysis, HyperMesh and ANSA lamps are relatively easy to use preprocessing tools, ANSYS, Nastran, and Abaqus are commonly used solver tools, and HyperView is a commonly used postprocessing software, which is compatible with most of the results file format. In terms of simulation types, Abaqus, Marc, ANSYS, and Nastran are good at solving the structural implicit linear and nonlinear problems of the system. Among them, Abaqus has the most powerful nonlinear solving function. LS-Dyna, Radioss, etc. are commonly used explicit nonlinear analysis software, which are often used to solve large deformation problems such as impact, collision, extrusion, and drop. Fluent, CFX, Star-ccm+, etc. are good at solving fluid mechanics problems in various occasions. How simulation simulation works in Battery pack thermal management The design of EV battery pack needs to ensure that the battery is always in a relatively comfortable temperature environment (battery temperature range 15~40℃; temperature difference between batteries: 5~10℃), so as to ensure long working life and good battery life of the whole vehicle Mileage performance, good work efficiency performance, convenient and fast charging series. In the pack design, the thermal management system design of the pack is completed with the help of thermal fluid simulation analysis. In the system design stage, thermal field simulation analysis can be performed on the pack, module or battery, and the appropriate cooling, heating and thermal insulation methods can be quickly selected according to the simulation results. In the cooling subsystem design stage, thermal field and flow field simulation analysis can be performed on the pack, module or battery. According to the simulation results, parameters such as cooling channel design, cooling medium, cooling inlet temperature and flow rate can be determined. With the help of simulation analysis, a large number of Pack thermal management design and part of the test work can be completed on the computer. A large number of design, manufacturing and testing work are optimized and omitted, and the design cost is also greatly reduced. What TRUMONY can provide? Trumony can provide R&D all-in-package solutions for customers. Including design, simulation and manufacturing the final products. At present, two solutions are very popular for BTMS: Tube type solution and plate type solution. Our main products are serpentine tube also called snake tube and water cooling plate. Here we did simulation for the simple structure snake tube. Attached are some simplified version of the test report for reference. Please feel free to reach out for more detailed information.

2022 02/21

Email to this supplier